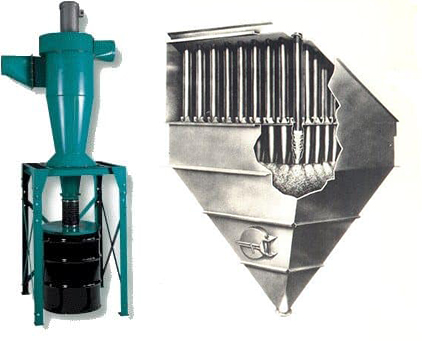

Cyclones use centrifugal force to separate particles from an air stream. Air enters at the top through a tangential inlet, where it spins as it travels downward. The force caused by the spin holds particles against the cone wall and dust continues to spiral downward until it falls into a drum or storage chamber. Clean air at the center of the cyclone passes through a tube, out of the top, and into the fan.

Cyclones are particularly well suited to severe loadings, and are frequently used as a prefilter to a baghouse or other type of high efficiency filter. A cyclone will hit efficiencies in the high 90’s on typical wood-working, grinding, sanding, or similar applications where particles have a high mass-to-surface area ratio. Fine particles, fibers, and other material that tends to float in the air will not be filtered very well by a cyclone. (In which case a simple after-filter is used to catch the fines.)

Multi-cyclones are exactly what they sound like, a matrix of small cyclones with common inlet, outlet, and dust discharge. Each cyclone measures only 6” to 10” diameter, which makes the system much more efficient than one large cyclone. This is because the centrifugal force is much higher in a small cyclone. Typical applications include high-temperature ash handling, and flue gas filtration from oil and wood-fired boilers.